Address

EDME - Elite Digital Machinery Enterprise, El-Imam Ali, Al Teroli, Cairo, Egypt

Business Hours

Sunday - Thursday

10 AM - 5 PM

*Once ordered Cura profile with initial configuration for this material will be available for download

Features:

ABS, while weaker and less rigid than PLA, is a tougher, lighter filament more suitable for some applications beyond purely hobbyist. ABS is a bit more durable, is about 25% lighter, and has four times higher impact resistance. ABS does require more effort to print than PLA because it’s more heat resistant and prone to warping. This calls for a heated bed and an extruder that is 40-50 degrees Celsius hotter. ABS, while by no means a heat resistant plastic, has superior heat deflection temperature compared to PLA and nylon.

ABS is a very strong and versatile material with great thermal resistance. It’s suitable for both indoor and outdoor use. Melts at a higher temperature than PLA. Higher melting temperature gives ABS great thermal resistance; your prints won’t show signs of deformation up to 98 °C.

ABS includes high wear-resistance synthetic rubber, which makes it very strong and impact resistant. And last but not least, it’s soluble in acetone! This makes it really easy to not only connect multiple parts together, but also allows you to smooth prints with acetone vapors. You still have to be careful when handling acetone, but it’s not anywhere near as dangerous as PLA solvents, for example.

On the other hand, thermal contraction is where ABS makes it really hard to successfully print something. And that’s especially true when printing anything larger. Even with the heatbed at 100 °C, your part may start lifting from the build plate and warp. This, and the unpleasant smell of ABS, is why you should consider getting an enclosure for your printer when printing with ABS. Or at least place the printer in a warm room.

If you need to use your print outside, or just need your print to be stronger, give ABS a shot.

After all, it’s what LEGO is made of.

The improved durability over PLA lends ABS to some more practical applications, such as prototyping and low-stress end-use parts.

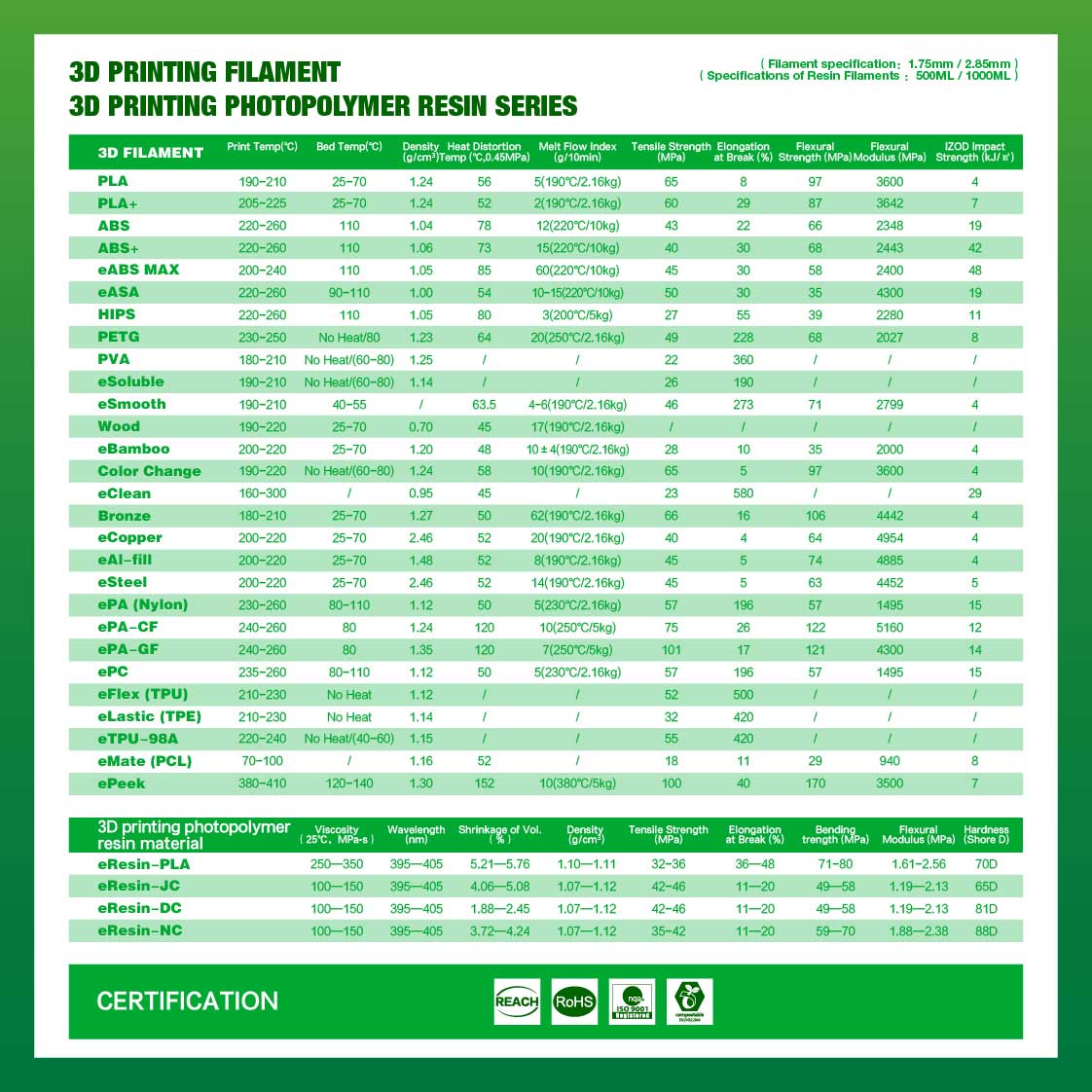

ABS Filament Specifications:

We have been a manufacturer and service company under the name of WerashCO for additive manufacturing since 2017 starting with largest scale FDM 3D printer in the middle east. Since then, we have expanded into new digital fabrication technologies for a variety of industries. Our aim is to manufacture reliable and industrial grade digital manufacturing machines in Egypt and dominate the Egyptian market in FDM (Fused Deposition Modeling) 3D Printers, Desktop CNC milling Machines, and Foam cutting machines.

Address

EDME - Elite Digital Machinery Enterprise, El-Imam Ali, Al Teroli, Cairo, Egypt

Business Hours

Sunday - Thursday

10 AM - 5 PM